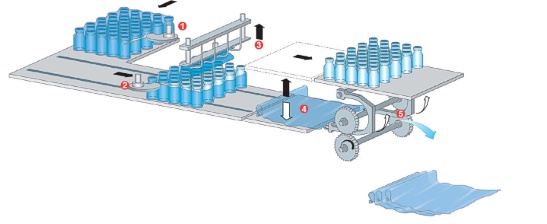

CAM MD Bottle un-packer

Automatic De-packer model "MD"

To ensure non-contamination of glass bottles during logistics components are being transported in shrink-wrapped collations. To process the bottles from this pack and feed them to the production line as efficiently as possible CAM proposes a completely automated solution using their de-packer MD.

The extremely compact structure with stainless steel panels integrates simple and safe movements, managed by a standard PLC system. The cutting of the protective film is carried-out by three spring- loaded heated blades; firstly the front side of the pack is cut followed by the simultaneous cutting of the two sides. At this point the upper section of cut film is lifted and held by grippers and the mechanical advancement moves the pack away on a platform, whilst uncovering the bottles.

At this point, the pack is enclosed by side walls which prevent bottles from falling-over. The platform then lifts and the side film is held back, completely freeing the bottles which are then pushed onto the outfeed deck.

Once bottles have been released, the platform is lowered and the film is picked-up by a second pair of grippers and transferred between two gears which guarantee mechanical discharge from the machine. Size change-over is made extremely simple by CAM's exclusive Mechanical Memory® system.