CAM AVC Cartoner

Automatic continuous motion vertical cartoner model "AVC"

The AVC continuous motion vertical cartoner has been designed by CAM to meet the packaging requirements, at medium-high speed of products for which the arrangement into carton and the final presentation could not be guaranteed by horizontal positioning./p>

All movements are controlled by closed-profile cams which have been subjected to surface hardening treatment. This feature, together with the heavy-duty structure, reduce maintenance operations and guarantee machine life for a long time.

As all CAM continuous motion cartoning machines, AVC is characterized by the exclusive carton erection system incorporating a 4-station turret, each station separately driven by closed-profile cams for carton pick-off at zero speed. This system allows for total and progressive carton pre-breaking to be carried out in a time period longer than the machine cycle.

Each carton erection station is composed of two suction-cup arms which, by pulling externally on the two adjacent faces of the carton, guarantee positive opening, whatever board grammage is used and even in the case of handling square-section formats.

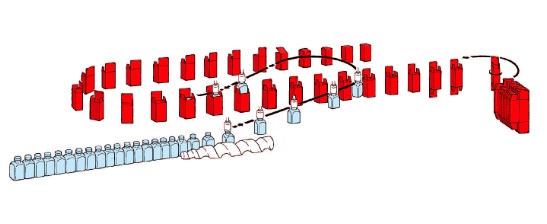

The wide range of product feeders available covers all possible packaging requirements of the market and is particularly suitable for bottles and jars. The introduction in vertical position eliminates all problems caused by horizontal introduction when traditional cartoners are used.

The structure of this machine makes it suitable for product manual feeding which can be carried out by many operators, thanks to the wide space dedicated to this operation.

AVC machine is also equipped with the Mechanical Memory® system, transforming complete size change-over into a series of rapid and pre-set operations, which can be carried-out by unskilled personnel in less than 10 minutes, eliminating the need for fine-tuning adjustments and allowing size change-over to coincide with actual production change-over.